Flat Electrical Interconnection Solutions

Renewing the way of designing, assembling and installing electrical cables for a sustainable future.

Renewing the way of designing, assembling and installing electrical cables for a sustainable future.

We believe that good cable design is not just about creating an intelligent solution of form and function.

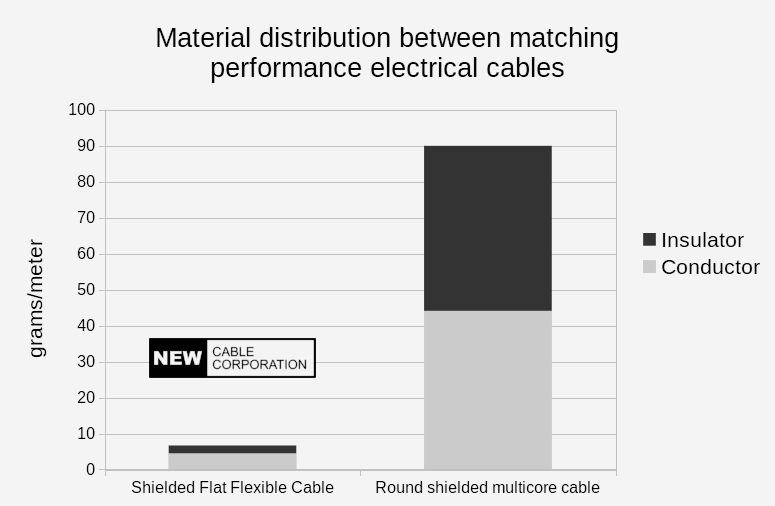

It is also a concrete action of increased sustainability in terms of savings in materials, weight and cost.

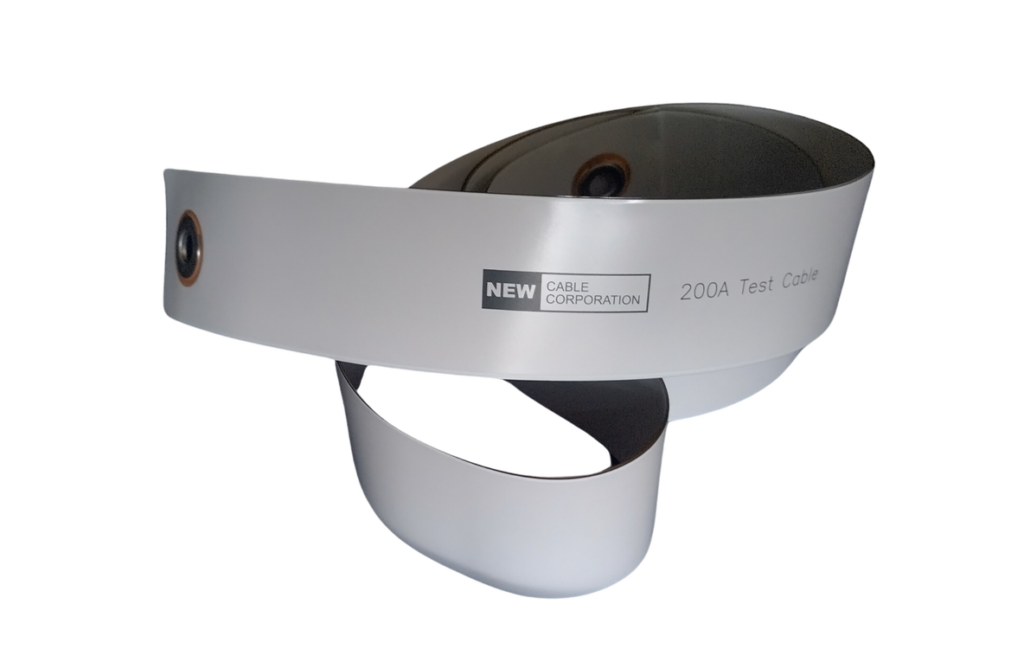

Our technology is designed to save up to 90% of the weight of the solution.

It offers supreme lifecycle impact in:

Collaborative design process

The ultimate objective of New Cable Corporation is to design and offer flat, flexible cable and harness solutions to save space, weight, material, and cost.

We aim to ensure that our products have the sustainable technology best suited to our customers’ requirements.

We correspond to customer specifications with procedures utilizing solution design levels, a mechanism where solution design is established through three customized stages. These levels are completed in collaboration with the customer.

After the solution design is finalized, we offer customized modes of production and lifecycle services to meet the customer standards.

Familiarize yourself with our services through the Level Approach presented in the following pages.

Solution Design Levels Testimonial:

“We welcomed the offer of a Joint Solutions Development project from New Cable Corporation as a step from ideation towards finding a concrete solution to our demand. The result of our first project was a prototype and pile of relevant data to be considered in further development. We will proceed with testing and iteration of the solution knowing this will massively enhance our own product performance and customer satisfaction” – Mr. Burrhus LANG, CEO – Leonhard Lang GmbH, Austria

Solution Design Levels Testimonial:

“Our goal was to develop a completely new product for Automotive markets. The product was completed with the flat cables from the New Cable Corporation. This project would not have been possible without the flat cables designed particularly for us. We were very happy about the flat cables New Cable Corporation provided to us. The cables worked as planned, power, data and heat transferred with ease.” – Mr. Juha ARTAMA, New Business Development Manager – NSG Group, Pilkington, Finland

The flat cable solution is designed together with the customer. New Cable Corporation has the knowledge on the electrical and material criteria and production knowledge whereas the Customer has the knowledge on the use case. The design criteria are agreed at the beginning of the project Level 1.

Project Management is agreed at the project Level 1. The overall project can be managed by the customer or by the New Cable Corporation. It is important that adequate project resources are appointed by the both parties to ensure smooth project completion.

The ownership of the designed product is agreed with the customer at the beginning of the project Level 1 or at later levels based on the customer requirements.

New Cable Corporation can make simple prototypes in-house but for more complex prototypes, the manufacturing is made with our production partners.

Yes it is. This can be agreed on any project Level based on the feasibility of the final cable solution.

This is possible. New Cable Corporation offers also consultancy that can be agreed directly with our sales.

New Cable Corporation is ready to negotiate on this topic.

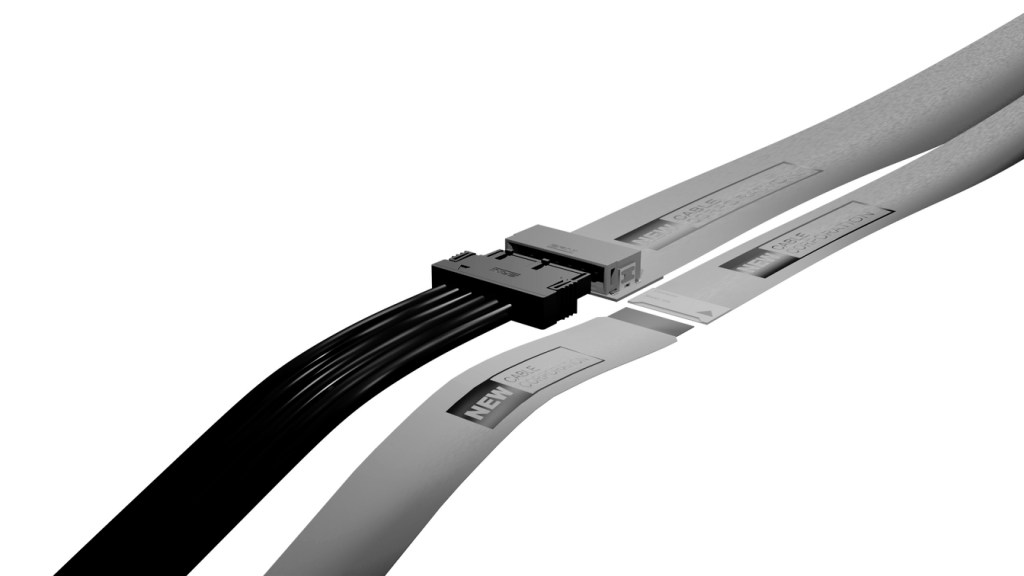

There is wide selection of connectors to choose. New Cable Corporations own Pocket Connector is one option. Depending on the application, most standard SMT and THT type connectors can also be used.

The flat cable can be used both, signal and power transfer. RF up to 10GHz and Power up to 400A are currently available.

New Cable Corporation has invented and patented new type of flat connector. It is one of the most light weight connectors in the market, with superior functionality.

Kaitoväylä 1

FI-90950 Oulu, FINLAND